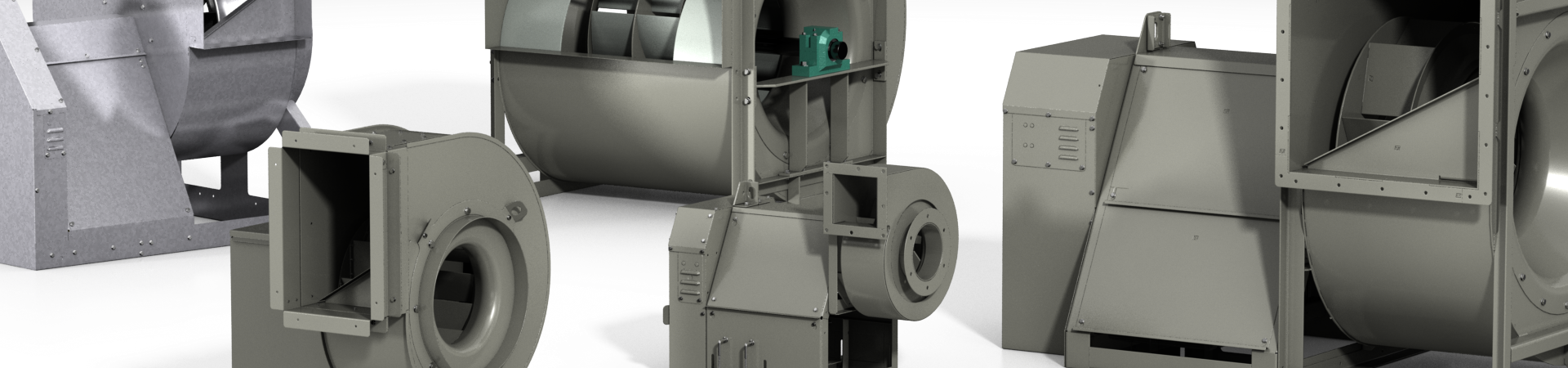

Blowers

Low flow and high-pressure air movement.

Centrifugal blowers have many applications including general ventilation, those requiring high airflows, manufacturing process, emergency or continuous high temperature, or grease-laden exhaust. Material choices range from galvanized steel, steel with corrosion resistant coatings, aluminum, fiberglass, or stainless steel. Designs are tiered to provide the most economical, practical and efficient operation by performance requirements and application.

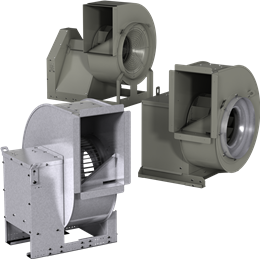

UTILITY SETS

Centrifugal utility blowers handle light-duty air applications (indoor, outdoor, supply or exhaust) for commercial or institutional. Units have many discharge configurations, which allow different airflow direction without system losses from duct turns.

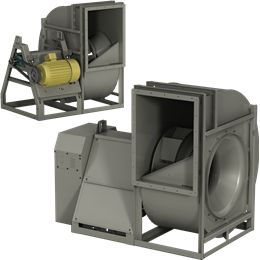

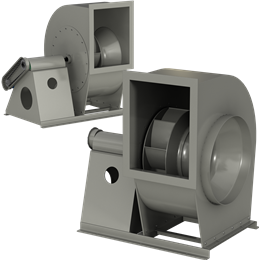

CENTRIFUGAL BLOWERS

Centrifugal blowers are applied to many applications including general ventilation, those requiring high airflows, manufacturing process, emergency or continuous high-temperature, or grease-laden exhaust. Blowers are fabricated of steel with a wide range of corrosion resistant coatings. Housing designs offered are either fully welded or lock-seam construction. Choice of backward-inclined or higher efficiency airfoil centrifugal wheels is available as standard. Options include aluminum or stainless steel wheels. Prior to shipment, each fan assembly is factory run and tested to meet acceptable vibration criteria.

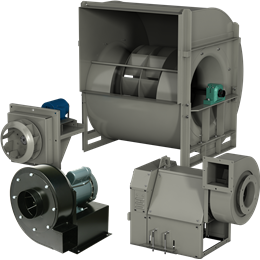

CENTRIFUGAL INDUSTRIAL FANS

Applications for industrial blowers include high airflow volumes, manufacturing process exhaust, grease-laden, and emergency or continuous high-temperature exhaust. Prior to shipment, each fan assembly is factory run and tested to meet acceptable vibration criteria. A wide range of protective coatings is available. Construction is aluminum or stainless steel (airstream only). Backward-inclined or higher efficiency airfoil centrifugal wheels are available with heavy-gauge steel, fully welded or lock-seam housing.

FIBERGLASS REINFORCED PLASTIC BLOWERS

Fiberglass reinforced plastic (FRP) centrifugal fans provide reliable and efficient operation in corrosive air movement applications. These fans can operate in a broad range of applications, however the typical use is in ducted systems. FRP fans can also be supplied with options for use in environments where a need for spark resistant construction exists.