Tunnels & Metros

Specialist systems for Rail & Metro, Road transverse, semi-transverse and Road longitudinal tunnel ventilation applications, with over 100 years of experience

Light at the end of the tunnel

Myair ventilation group provides general ventilation and high temperature smoke extract solutions for:

- Road tunnels,

- Rail tunnels

- Metros systems

- Service tunnels

- Cable tunnels

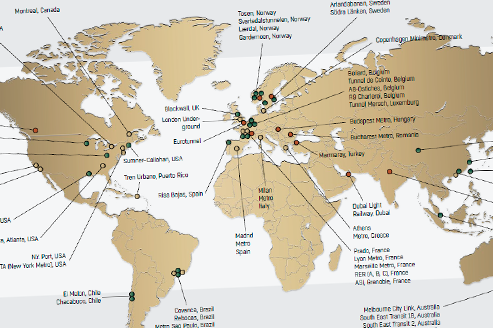

Myair ventilation group products have been installed in underground structures throughout the world and the technology, innovation

Effective ventilation is an essential requirement for life support underground.

Toxic and inflammable gases must be diluted to a safe level; dust and smoke dispersed; excessive heat should be relieved; and escape routes must be kept clear from smoke. Pollution emitted by trains and road vehicles must be removed to provide an acceptable and safe environment. The heat from a train may need to be removed by forced ventilation to ensure that the temperature is acceptable to both people and equipment.

Length of exposure and concentration of carbon monoxide are the important factors in the progressive effects of loss of alertness, headache and unconsciousness. Other products of car exhausts such as nitrogen and sulphur oxides can also have negative health effects of drivers.

As vehicles become cleaner and more efficient and alternative fuel sources become more common, the day to day ventilation requirement for tunnels will change meaning far more focus is required on the fire safety element of tunnel ventilation for the long term safety of users.

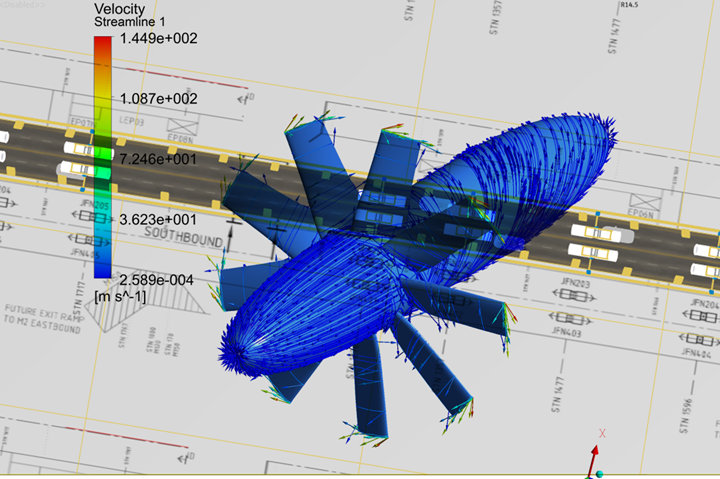

Myair ventilation group has a design and CFD Centre of Excellence based in the UK, supported by local specialists. The Design team are focused on delivering the optimum design, tailored to local regulatory requirements, optimising air quality, fire safety, installed cost and full life cycle costs.

Our engineering department are able to assist in making sure all calculations are correct and the products selected meet all requirements.

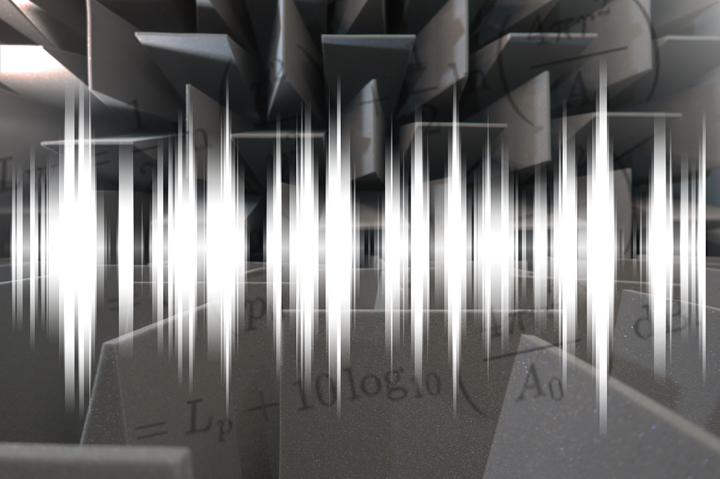

FAT’s are conducted at our tunnelling Centre of Excellence in the UK. Our dedicated lab conducts regular FAT’s for our clients all over the world. This also gives our customers the opportunity to inspect the factory and understand the manufacturing process so they can have confidence in our solution.

Due to the bespoke nature of tunnel ventilation design, we provide extensive support (including on-site) for the installation and commissioning phase.

We have a global network of Myair ventilation group operating companies and local parnters with extensive tunnel ventilation experience all supported by the dedicated project management team in the UK.

Myair ventilation group are on hand for support through every stage. Right from the design stage through to installation and beyond. We’re always happy to help from our Centre of Excellence in the UK to our extended network throughout the world.